Fill Out a Valid Pre Trip Inspection Checklist Form

Before hitting the road, ensuring that a vehicle is safe and operational is crucial, especially for commercial drivers. The Pre Trip Inspection Checklist form serves as a vital tool in this process, guiding drivers through a comprehensive examination of their vehicle. This checklist typically includes sections for inspecting the engine, brakes, lights, tires, and other essential components. By systematically reviewing these areas, drivers can identify potential issues before they lead to breakdowns or accidents. Additionally, the form often emphasizes the importance of checking fluid levels, ensuring that mirrors are properly adjusted, and confirming that safety equipment is in place. This proactive approach not only enhances safety but also helps in compliance with regulatory requirements. Ultimately, completing the Pre Trip Inspection Checklist can contribute to smoother operations and greater peace of mind for drivers and fleet managers alike.

Common mistakes

-

Skipping Sections: Many individuals overlook certain sections of the checklist, thinking they are not relevant. Each part of the form is designed to ensure safety and compliance, so it’s crucial to complete every section thoroughly.

-

Inaccurate Information: Providing incorrect details, such as vehicle identification numbers or tire pressure readings, can lead to serious consequences. Always double-check the information before submitting the form.

-

Failure to Sign and Date: Some people forget to sign and date the checklist. This step is essential for accountability and serves as proof that the inspection was completed.

-

Neglecting to Report Issues: If any problems are identified during the inspection, failing to report them is a common mistake. Documenting issues ensures they are addressed promptly, maintaining safety on the road.

Preview - Pre Trip Inspection Checklist Form

Class A CDL

®

®

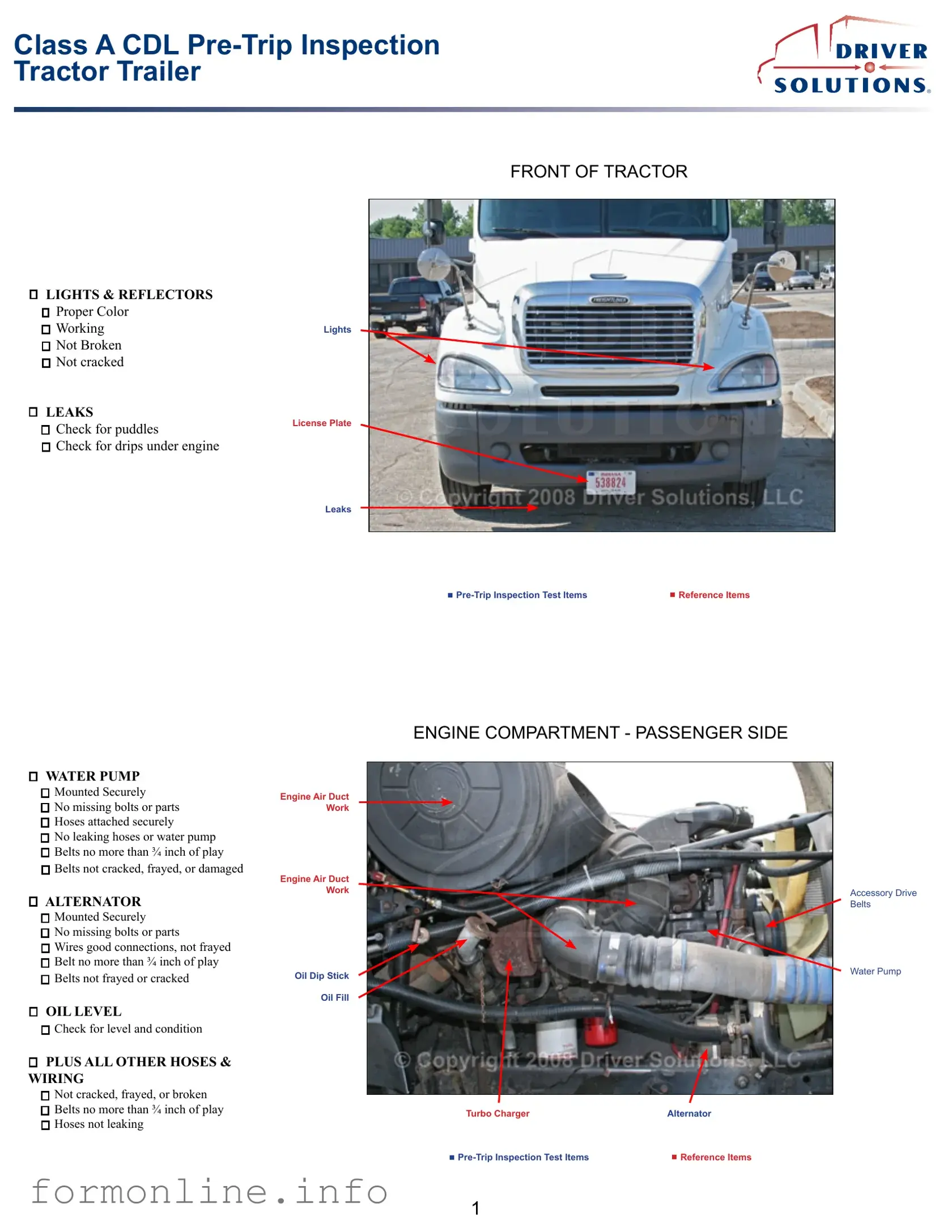

FRONT OF TRACTOR

LIGHTS & REFLECTORS o Proper Color

o Working

o Not Broken o Not cracked

LEAKS

o Check for puddles

o Check for drips under engine

Lights

License Plate

Leaks

Reference Items |

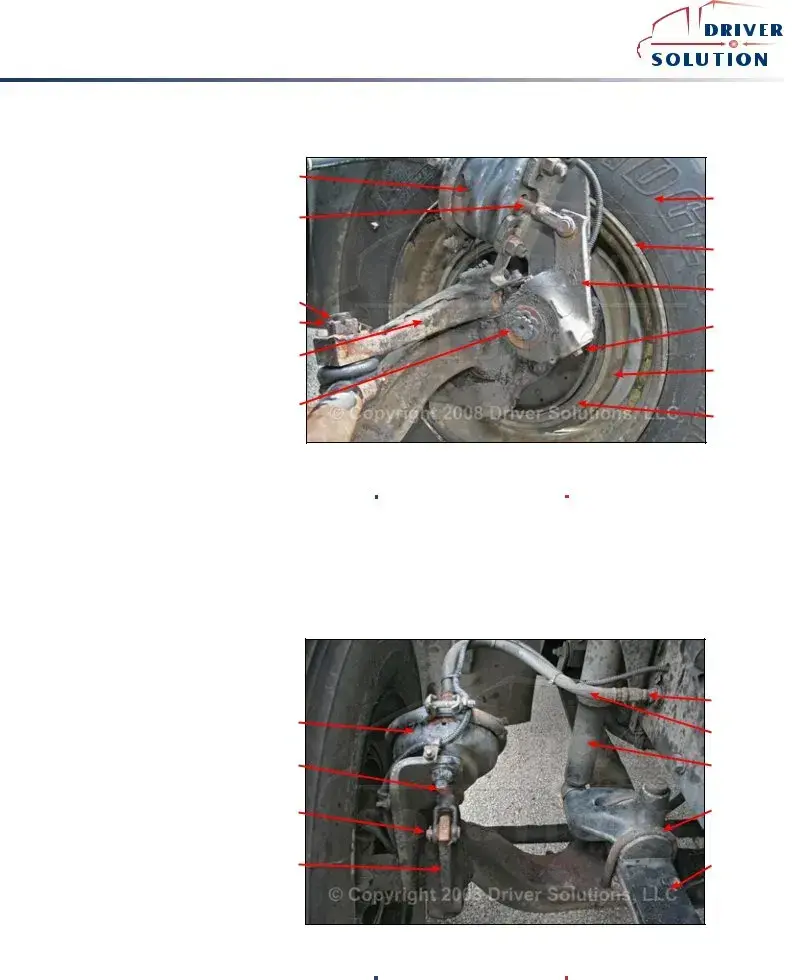

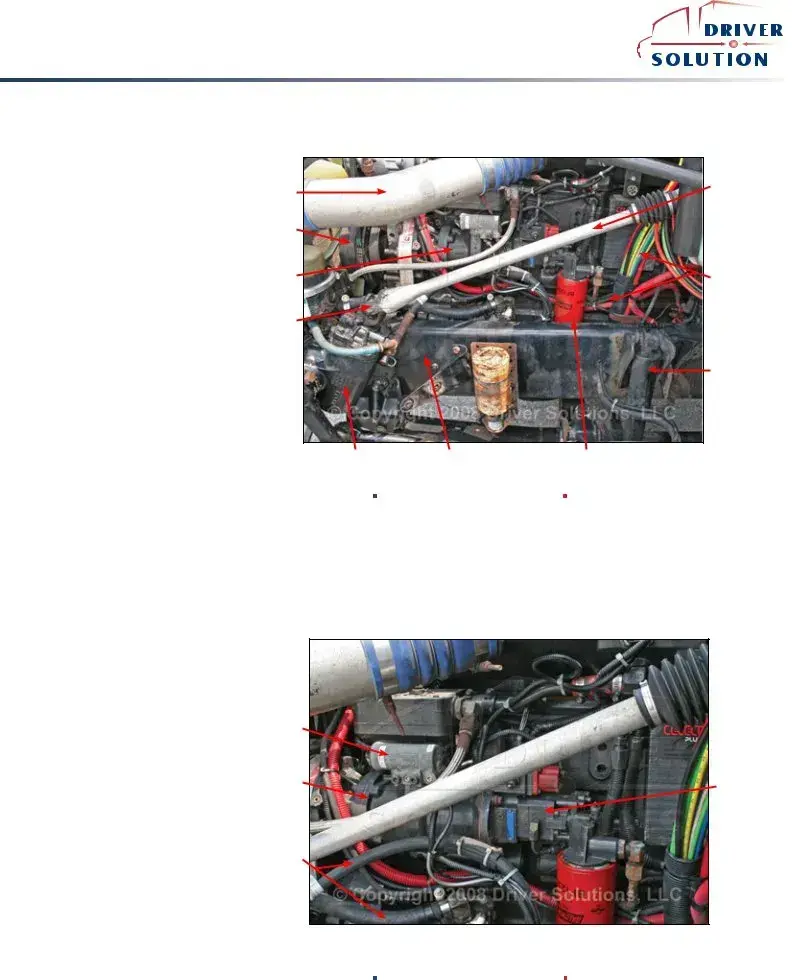

ENGINE COMPARTMENT - PASSENGER SIDE

WATER PUMP o Mounted Securely

o No missing bolts or parts o Hoses attached securely

o No leaking hoses or water pump o Belts no more than ¾ inch of play

o Belts not cracked, frayed, or damaged

ALTERNATOR

o Mounted Securely

o No missing bolts or parts

oWires good connections, not frayed

oBelt no more than ¾ inch of play

oBelts not frayed or cracked

OIL LEVEL

oCheck for level and condition

PLUS ALL OTHER HOSES & WIRING

oNot cracked, frayed, or broken

oBelts no more than ¾ inch of play o Hoses not leaking

Engine Air Duct Work

Engine Air Duct Work

Oil Dip Stick

Oil Fill

|

Accessory Drive |

|

Belts |

|

Water Pump |

Turbo Charger |

Alternator |

Reference Items |

1

Class A CDL

®

®

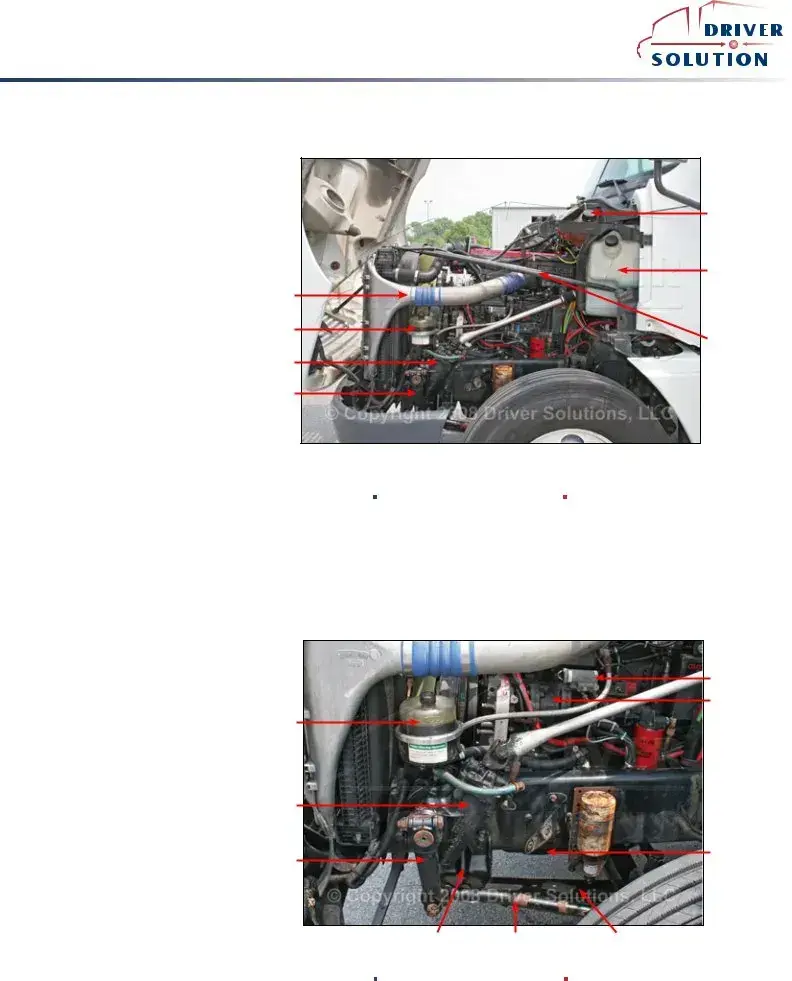

ENGINE COMPARTMENT - DRIVER SIDE

COOLANT

oCheck for level and condition

oHoses attached and not leaking

POWER STEERING RESERVOIR

oMounted properly

oHoses attached and not leaking

oCheck for level and condition

AIR COMPRESSOR

oMounted Securely

oNo missing bolts or parts

oNo air leaks at lines

oCheck if gear or belt driven

oBelt no more than ¾ inch of play

oBelts not cracked or frayed

STEERING GEAR BOX

oMounted properly

oNo missing parts, nuts or bolts o Lines and hoses not leaking or broken

|

Engine Coolant |

|

Reservoir |

|

Windsheild |

|

Washer Fluid |

|

Reservoir |

Engine Air Duct |

|

Work |

|

Power Steering |

|

Reservoir |

Radiator Brace |

|

|

Steering Gear |

|

Box |

|

Pitman Arm |

|

Reference Items |

POWER STEERING RESERVOIR |

ENGINE COMPARTMENT - DRIVER SIDE CON’T |

||

|

|

|

|

o Mounted properly |

|

|

|

o Hoses attached and not leaking |

|

|

|

o Check for level and condition |

|

|

|

AIR COMPRESSOR |

|

|

|

o Mounted Securely |

Power Steering |

|

|

o No missing bolts or parts |

|

|

|

Reservoir |

|

|

|

o No air leaks at lines |

|

|

|

o Check if gear or belt driven |

|

|

|

o Belt no more than ¾ inch of play |

|

|

|

o Belts not cracked or frayed |

|

|

|

STEERING GEAR BOX |

Steering Gear |

|

|

Box |

|

|

|

o Mounted properly |

|

|

|

o No missing parts, nuts or bolts |

|

|

|

o Lines and hoses not leaking or |

Pitman Arm |

|

|

broken |

|

|

|

|

|

|

|

STEERING LINKAGE |

|

|

|

o Pitman arm, Drag link, Steering |

|

|

|

knuckle, Tie rods and tie rod ends |

|

|

|

o Not cracked, bent or broken |

Spring Mount |

Drag Link |

Leaf Spring |

o Castle nuts and cotter pins |

|

|

|

o Not missing and in place |

|

|

|

Reference Items |

Air Governor

Air Compressor

Engine Oil Pan

2

Class A CDL

®

®

AIR COMPRESSOR o Mounted Securely

o No missing bolts or parts o No air leaks at lines

o Check if gear or belt driven

o Belt no more than ¾ inch of play o Belts not cracked or frayed

STEERING GEAR BOX

o Mounted properly

oNo missing parts, nuts or bolts o Lines and hoses not leaking or broken

ENGINE COMPARTMENT - DRIVER SIDE CON’T

Engine Air Duct

Work

Fan Belts

Gear Driven Air

Compressor

Steering

Steering Column

Additional Hoses & Wiring

Shock Absorber

Steering Gear Box |

Frame Rail |

Fuel Filter |

Reference Items |

||

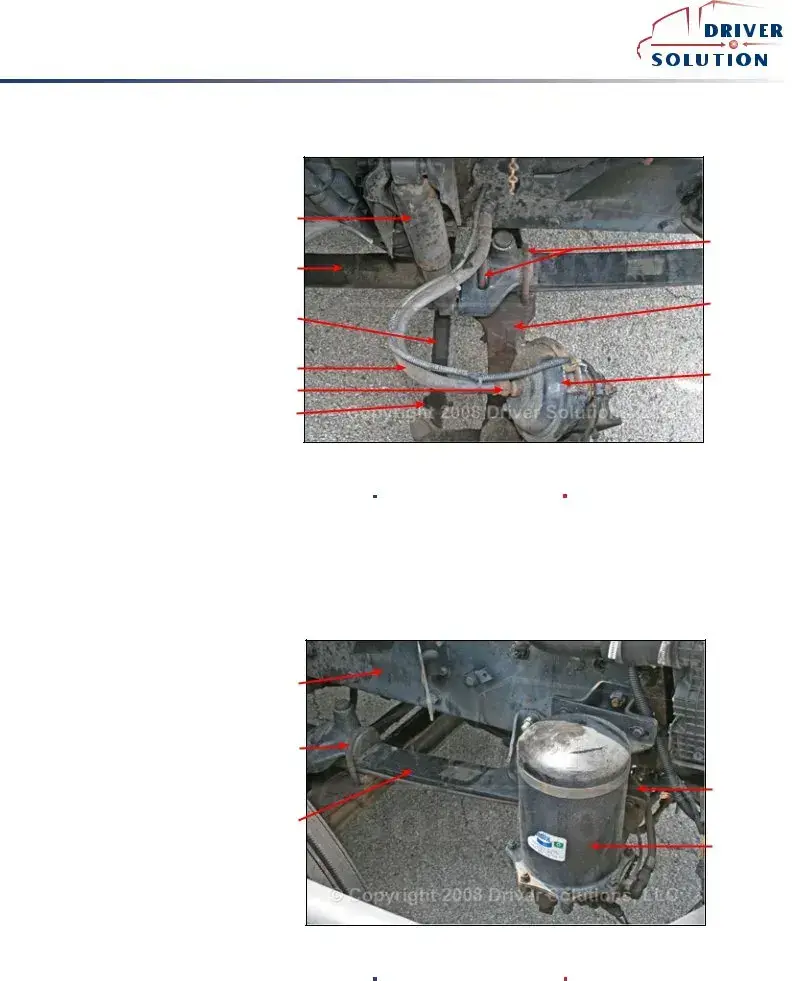

ENGINE COMPARTMENT - AIR COMPRESSOR

AIR COMPRESSOR o Mounted Securely

o No missing bolts or parts o No air leaks at lines

o Check if gear or belt driven

o Belt no more than ¾ inch of play o Belts not cracked or frayed

Air Governor

Gear Driven Air Compressor

Hoses

Fuel Pump

Reference Items |

3

Class A CDL

®

®

FRONT SUSPENSION

LEAF SPRINGS

o Not shifted or out of place

oNot cracked, broken or missing

SPRING MOUNTS

oMounted securely- front, back, and

oNot cracked or broken

SHOCK ABSORBER

oMounted Securely

oNot bent or dented o Not leaking

Shock Absorber

Leaf Spring

Tie Rod

Air Hose

Air LIne

Tie Rod End

Axle |

Service Brake |

Chamber |

Reference Items |

LEAF SPRINGS

o Not shifted or out of place

oNot cracked, broken or missing

SPRING MOUNTS

oMounted securely- front, back, and

oNot cracked or broken

SHOCK ABSORBER

oMounted Securely

oNot bent or dented o Not leaking

FRONT SUSPENSION CON’T

Frame Rail

Leaf Spring

Air Dryer location varies depending on model.

Located either behind the front bumper or behind the fuel tank.

Reference Items |

4

Spring Mount

Air Dryer

Class A CDL

®

®

HOSES AND LINES |

|

FRONT BRAKES |

|

|

|

||

o Mounted securely |

Service Brake |

|

|

o |

Not leaking |

|

|

o |

Not cracked or frayed |

Chamber |

|

|

Tire |

||

|

|

|

|

CHAMBER |

Push Rod |

|

|

o Mounted securely |

|

|

|

o Not dented or damaged |

|

Wheel |

|

o |

Not leaking |

|

|

SLACK ADJUSTER |

|

Slack Adjuster |

|

o |

No more than 1 inch of free play at |

Castle Nut |

|

the push rod with the brakes released. |

Cotter Pin |

Adjustment Nut |

|

o |

Not bent, broken, loose, or missing |

|

|

|

|

||

parts |

Steering |

|

|

|

|

Knuckle |

Brake Drum |

DRUMS |

|

||

|

|

||

o |

Not cracked, broken or dented |

|

|

o |

No oil leaking from inner oil seal, |

Snap Ring |

|

free of debris |

|

Brake Lining |

|

LININGS |

|

|

|

oNo cracked, broken or missing parts o Not less than ¼ inch in thickness

Reference Items |

HOSES AND LINES o Mounted securely o Not leaking

o Not cracked or frayed

CHAMBER

o Mounted securely

oNot dented or damaged

oNot leaking

SLACK ADJUSTER

oNo more than 1 inch of free play at the push rod with the brakes released.

oNot bent, broken, loose, or missing parts

DRUMS

oNot cracked, broken or dented

oNo oil leaking from inner oil seal, free of debris

LININGS

oNo cracked, broken or missing parts

oNot less than ¼ inch in thickness

FRONT BRAKES CON’T

Service Brake

Chamber

Push Rod

Clevis Pin &

Cotter Pin

Slack Adjuster

Reference Items |

Air Line

Air Hose

Shock Absorber

Spring

5

Class A CDL

®

®

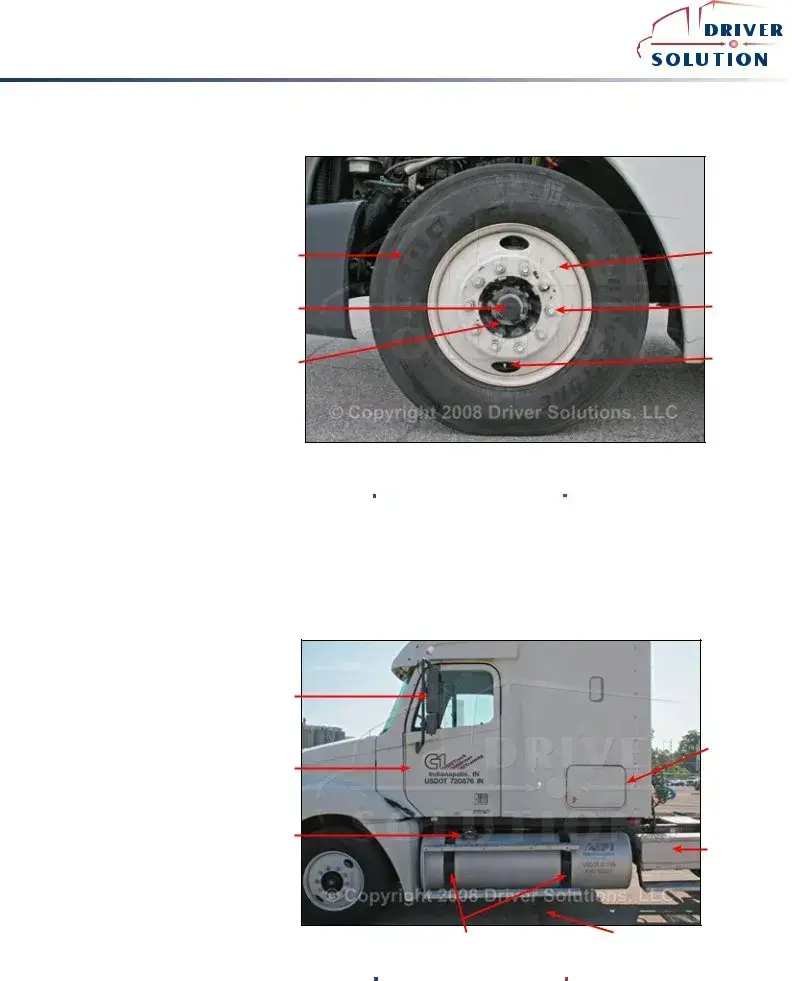

FRONT WHEEL

TIRES

oProper inflation – company or manufacturer specification

o No bulges, cuts, or retreads

o Minimum tread depth of 4/32”

RIMS

oNot bent, cracked, No welding repairs.

LUG NUTS

oNone are missing

oTight – no shinny threads, or rust trails

OUTER HUB OIL SEALS

oNot leaking, no missing bolts o Proper oil level

Tire |

Wheel |

|

Hub Oil |

Lug Nut |

|

Reservior |

||

|

||

Outer Hub |

Valve Cap |

|

Oil Seal |

|

Reference Items |

DRIVER FUEL AREA

DRIVER’S DOOR

oDoor opens and closes properly

oSeal is in good condition

DRIVER’S MIRRORS

oClean and free of obstruction

oNot cracked, broken, or damaged

oMounted securely

FUEL TANK

oMounted securely

o Not leaking

o Seal in cap OK

Mirror |

Storage |

Compartment |

Door |

Cap & Seal |

Battery Box & |

Cover |

Saddle Mounts |

Leaks |

Reference Items |

6

Class A CDL

®

®

AIR LINES & ELECTRIC LINE o Not cracked, frayed, cut, or kinked o Mounted securely at the glad hands o Not leaking

BEHIND THE CAB

BATTERY BOX & BATTERIES o Box is mounted properly

o Batteries are secure in the box o Lid secure

o Connections not corroded

CATWALK

o Mounted properly

oNot, missing, or damaged

oFree of obstructions

DRIVE SHAFT

oNot bent, or damaged

oCoupling,

EXHAUST SYSTEM

oSecurely mounted

oNot dented or damaged

oNot leaking

FRAME

oNot cracked, or damaged

oNo missing bolts

oNo illegal welds

LIGHTS & REFLECTORS

oClean and working

Lights & |

|

Reflectors |

|

Electrical Line |

Exhaust |

Glad Hand |

|

Service & |

|

Emergency |

|

Airlines |

Drive Shaft |

|

|

Battery Box & |

|

Batteries |

|

Frame |

Catwalk |

Reference Items |

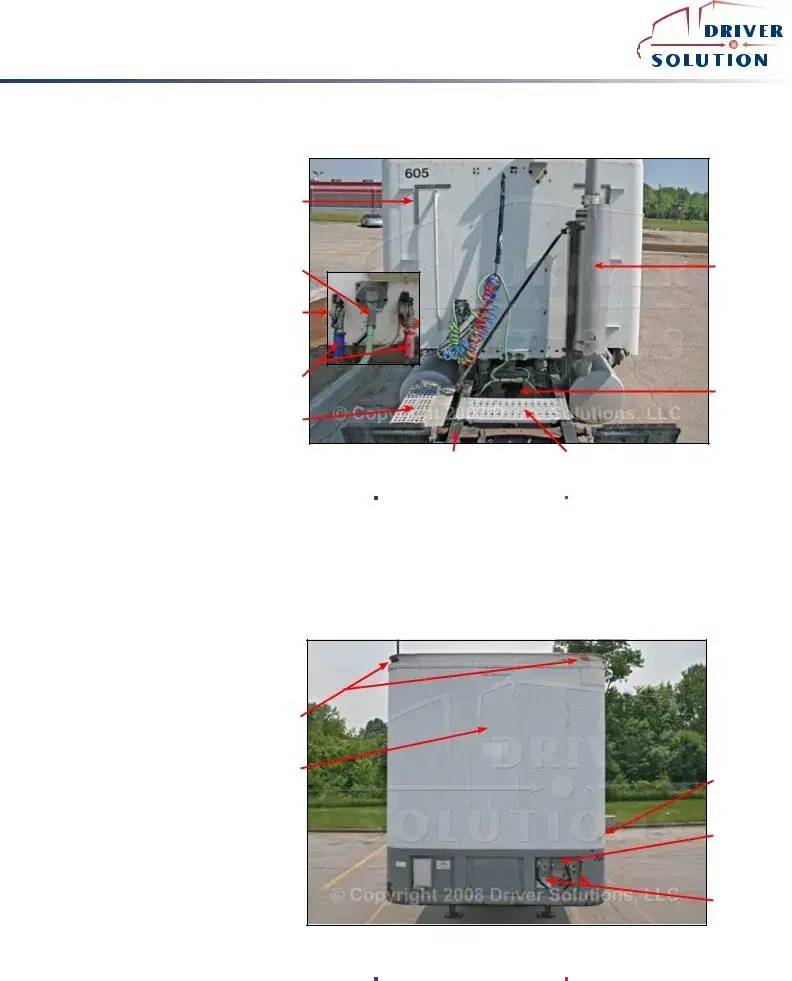

FRONT OF TRAILER

HEADER BOARD

oNo holes or missing rivets

LIGHTS & REFLECTORS

oNone broken, cracked, or missing

oWorking and proper color of amber

Lights |

Header Board |

Height Sticker

Electric Hookup

Air Line

Reference Items |

7

Class A CDL

®

®

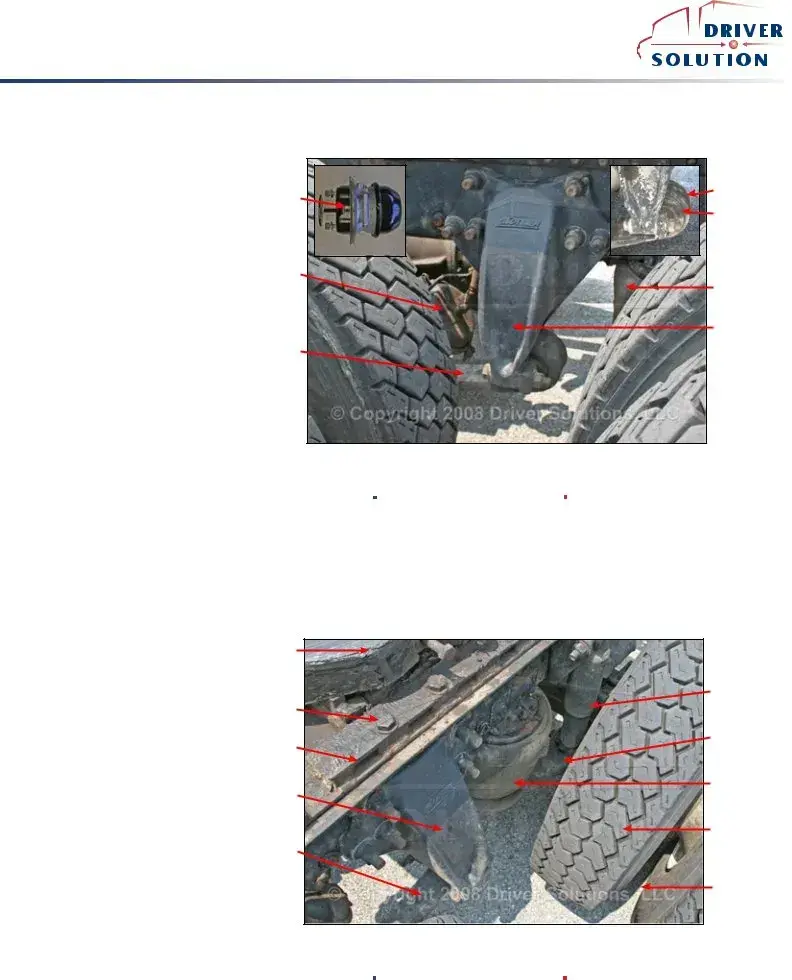

DRIVE AXLE SUSPENSION

CONTROL ARM MOUNT o Mounted securely

o Not bent, broken or damaged

CONTROLARM

oMounted securely – front, back, and

o Not cracked, or broken

SHOCK ABSORBER

o Mounted Securely

oNot bent, dented or leaking

TORSION BAR

oMounted Securely

oNot bent, broken or damaged

AIR BAGS

oMounted Securely

o Not leaking

Spring Brake |

Torsion Bar |

|

|

Chamber |

Control Arm |

|

|

Spring Brake |

|

Chamber |

Air Bag |

|

|

|

Control Arm |

|

Mount |

Control Arm |

|

Reference Items |

DRIVE AXLE SUSPENSION CON’T & FIFTH WHEEL

CONTROL ARM MOUNT o Mounted securely

o Not bent, broken or damaged

CONTROLARM

oMounted securely – front, back, and

o Not cracked, or broken

SHOCK ABSORBER

o Mounted Securely

oNot bent, dented or leaking

TORSION BAR

oMounted Securely

oNot bent, broken or damaged

AIR BAGS

oMounted Securely

o Not leaking

Skid Plate |

|

|

Shock Absorber |

Mounting |

|

Bolts |

|

Locking |

Spring |

|

|

Pins |

|

Control Arm |

Air Bag |

|

|

Mount |

|

|

Tire |

Control Arm |

|

|

Space |

Reference Items |

8

Class A CDL

®

®

HOSES AND LINES o Mounted securely o Not leaking

o Not cracked or frayed

CHAMBER

o Mounted securely

oNot dented or damaged

oNot leaking

SLACK ADJUSTER

oNo more than 1 inch of free play at the push rod with the brakes released.

oNo bent, broken, loose, or missing parts

DRUMS

oNot cracked, broken or dented

oNo oil leaking from inner oil seal, free of debris

LININGS

oNo cracked, broken or missing parts

oNot less than ¼ inch in thickness

DRIVE BRAKES & DRIVE SHAFT

Drive Shaft

Universal Joint

Differential

Reference Items |

Air Line

Service Brake Chamber

Frame

Brake Chamber Mount

Slack Adjuster

TIRES

oProper inflation - company or manufacturer specification.

o No bulges or cuts, can have retreads o Minimum tread depth of 2/32”

RIMS

oNot bent or cracked

oNo welding repairs

LUG NUTS

oNone missing

oTight – no shinny threads, or rust trails

OUTER AXLE SEAL

oNot leaking, no missing bolts

SPACE OR SPACER

oCheck for objects between wheels

oCheck for proper spacing

Lug Nuts

Outer Axle Seal

DRIVE WHEELS

Tire

Bud Rim

Dayton Rim |

Spacer |

Reference Items |

9

Class A CDL

®

®

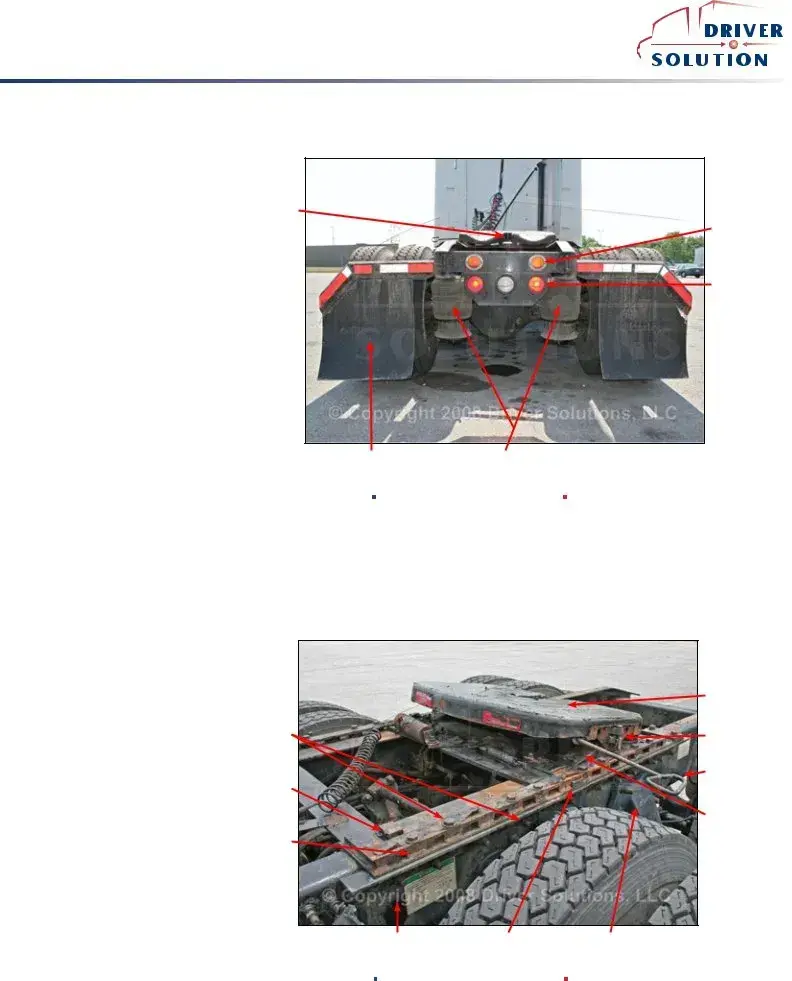

REAR OF TRACTOR

LIGHTS & REFLECTORS o Not cracked, or broken

o Working and proper color

SPLASH GUARDS

oNot missing or torn and properly mounted

Locking Jaws |

|

|

Reflectors |

|

Lights |

Splash Guard |

Air Bags |

Reference Items |

MOUNTING BOLTS

oNone missing or broken

RELEASE ARM

oNot bent, broken, or damaged

oEngaged in the lock position

LOCKING PINS

oNo missing or broken parts

oEngaged and locked

PLATFORM

oSecurely holds skid plate

oNot cracked, or broken

SKID PLATE

oMounted properly on the platform

oProperly greased

oTilting freely

Mounting Bolts

Slide Stops (all 4 corners)

COUPLING SYSTEM

Skid Plate |

Pivot Pin |

Release Arm |

Platform |

KING PIN |

Welds |

oNot broken, bent, or damaged

APRON

oNo bends or damage to visible portions

GAP

oCheck that the trailer apron is lying flat on the fifth wheel skid plate

Frame |

Slide Locking Pin |

Spring Mount |

JAWS |

Reference Items |

|

|

|

|

o Check that the locking jaws are fully |

|

|

closed around the shank of the king pin |

10 |

|

Other PDF Templates

Adp Ipay - Employees can use their pay stubs for securing loans or mortgages as proof of income.

When engaging in the sale or purchase of a mobile home, it is essential to utilize the proper documentation to protect both parties involved in the transaction. The Missouri Mobile Home Bill of Sale serves this purpose by providing a clear record of the transfer of ownership. For additional details on how to properly complete this transaction, refer to the Mobile Home Bill of Sale, which outlines the necessary steps and requirements to ensure a seamless process.

Patient Demographic Form PDF - Capture the zip code to complete the patient's address details.

Documents used along the form

The Pre Trip Inspection Checklist form is a vital tool for ensuring the safety and readiness of vehicles before they hit the road. Alongside this checklist, several other forms and documents are commonly used to maintain compliance and enhance safety protocols. Below is a list of these essential documents.

- Vehicle Maintenance Log: This document records all maintenance activities performed on the vehicle, including oil changes, tire rotations, and repairs. It helps track the vehicle's overall condition and ensures timely servicing.

- Driver's Daily Log: This log captures a driver's hours of service, including driving time, rest breaks, and off-duty hours. It is crucial for compliance with federal regulations regarding driving limits.

- Accident Report Form: In the event of an accident, this form is used to document details such as the time, location, and circumstances of the incident. It aids in insurance claims and legal matters.

- Fuel Purchase Receipt: This receipt provides proof of fuel purchases made during trips. It is important for tracking fuel expenses and can be used for reimbursement purposes.

- Inspection Report: After a vehicle inspection, this report summarizes findings and any necessary repairs. It helps ensure that vehicles meet safety standards and regulatory requirements.

- Route Plan: This document outlines the planned route for a trip, including stops and estimated travel times. It assists in logistics and helps drivers stay on schedule.

- Non-disclosure Agreement (NDA): A critical document for protecting sensitive information, ensuring that shared data remains confidential and secure. For more details, you can visit https://georgiapdf.com.

- Emergency Contact List: This list contains contact information for key personnel, emergency services, and roadside assistance. It ensures that drivers have access to help when needed.

Using these documents in conjunction with the Pre Trip Inspection Checklist fosters a comprehensive approach to vehicle safety and compliance. Together, they help ensure that drivers are prepared and that vehicles are roadworthy, contributing to safer travel for everyone.

Similar forms

The Vehicle Inspection Report serves a similar purpose to the Pre Trip Inspection Checklist. Both documents are designed to ensure that vehicles are in safe operating condition before they are used. The Vehicle Inspection Report typically includes a comprehensive list of components that need to be checked, such as brakes, lights, and tires. Like the Pre Trip Inspection Checklist, it emphasizes the importance of identifying any potential issues that could lead to safety hazards during operation. Regular completion of this report helps maintain vehicle safety standards and compliance with regulatory requirements.

The North Carolina Motor Vehicle Bill of Sale form is a crucial document in the vehicle transfer process that ensures proper registration and titling within the state. It captures essential details such as the make, model, year, and VIN of the vehicle, as well as the sale price and date of transaction. For more information on this important form, visit autobillofsaleform.com/north-carolina-motor-vehicle-bill-of-sale-form/.

The Daily Vehicle Inspection Log is another document that parallels the Pre Trip Inspection Checklist. This log is used by drivers to record their observations and findings regarding the vehicle’s condition each day. Similar to the Pre Trip Inspection Checklist, it focuses on key areas such as fluid levels, tire pressure, and functionality of safety equipment. The Daily Vehicle Inspection Log provides a systematic approach to monitoring vehicle health, ensuring that any problems are documented and addressed promptly, thereby enhancing overall safety and reliability.

The Maintenance Work Order is also comparable to the Pre Trip Inspection Checklist, albeit with a different focus. This document outlines the necessary repairs or maintenance tasks identified during inspections. While the Pre Trip Inspection Checklist is proactive, aimed at preventing issues before they arise, the Maintenance Work Order is reactive, detailing actions taken to rectify problems. Both documents play a critical role in vehicle upkeep, ensuring that any issues discovered during inspections are formally addressed and tracked for future reference.

The Safety Inspection Checklist shares similarities with the Pre Trip Inspection Checklist in that both are utilized to evaluate safety measures. The Safety Inspection Checklist may cover a broader range of safety protocols, including equipment and workplace conditions, but the fundamental goal remains the same: to identify and mitigate risks. By systematically reviewing safety features and compliance with regulations, both documents contribute to a culture of safety and accountability within transportation operations.

Lastly, the Driver's Daily Log is akin to the Pre Trip Inspection Checklist in that it serves as a record-keeping tool for drivers. While the Pre Trip Inspection Checklist focuses on vehicle condition before operation, the Driver's Daily Log tracks hours of service, rest breaks, and driving conditions throughout the day. Both documents are essential for ensuring compliance with transportation regulations and promoting safe driving practices. Together, they provide a comprehensive overview of a driver’s responsibilities and the vehicle’s readiness for operation.

Dos and Don'ts

When filling out the Pre Trip Inspection Checklist form, attention to detail is crucial. Below are five important dos and don’ts to keep in mind.

- Do review the entire checklist thoroughly before starting your inspection.

- Do ensure that all sections are completed accurately and legibly.

- Do use a pen or pencil that is easy to read; avoid using colors that may fade.

- Don't rush through the inspection; take your time to ensure nothing is overlooked.

- Don't leave any section blank; if something doesn’t apply, indicate that clearly.

By following these guidelines, you can help ensure that the Pre Trip Inspection Checklist is filled out correctly and efficiently.

Key takeaways

Filling out the Pre Trip Inspection Checklist form is crucial for ensuring safety and compliance. Here are five key takeaways to keep in mind:

- Thoroughness is essential. Every item on the checklist must be inspected carefully. Skipping steps can lead to serious safety issues.

- Document everything. Accurate records help in maintaining accountability. If an issue arises, having a detailed checklist can protect you legally.

- Timing matters. Complete the inspection before each trip. This proactive approach can prevent breakdowns and accidents.

- Be aware of your responsibilities. As the driver, you are responsible for the vehicle’s condition. Take this duty seriously.

- Report any issues immediately. If you find a problem during the inspection, address it right away. Delaying repairs can lead to bigger problems down the road.

Utilizing the Pre Trip Inspection Checklist effectively can enhance safety for everyone on the road.

How to Use Pre Trip Inspection Checklist

Completing the Pre Trip Inspection Checklist is essential for ensuring that a vehicle is safe and ready for operation. Following these steps will help you fill out the form accurately and efficiently.

- Begin by gathering all necessary materials, including the Pre Trip Inspection Checklist form and a pen or pencil.

- Write the date at the top of the form to indicate when the inspection is taking place.

- Identify the vehicle by entering its make, model, and identification number.

- Check each section of the checklist thoroughly. This includes areas such as brakes, lights, tires, and fluid levels.

- For each item inspected, mark it as “satisfactory” or “unsatisfactory” based on your findings.

- If any issues are found, provide a brief description in the comments section next to the relevant item.

- After completing the checklist, sign and date the form at the bottom to certify that the inspection has been conducted.

- Submit the completed form to the appropriate authority or keep it for your records as required.